Provide a one-stop solution

我们承诺:客户第一 质量第一 服务第一

Our company profile

ABOUT US

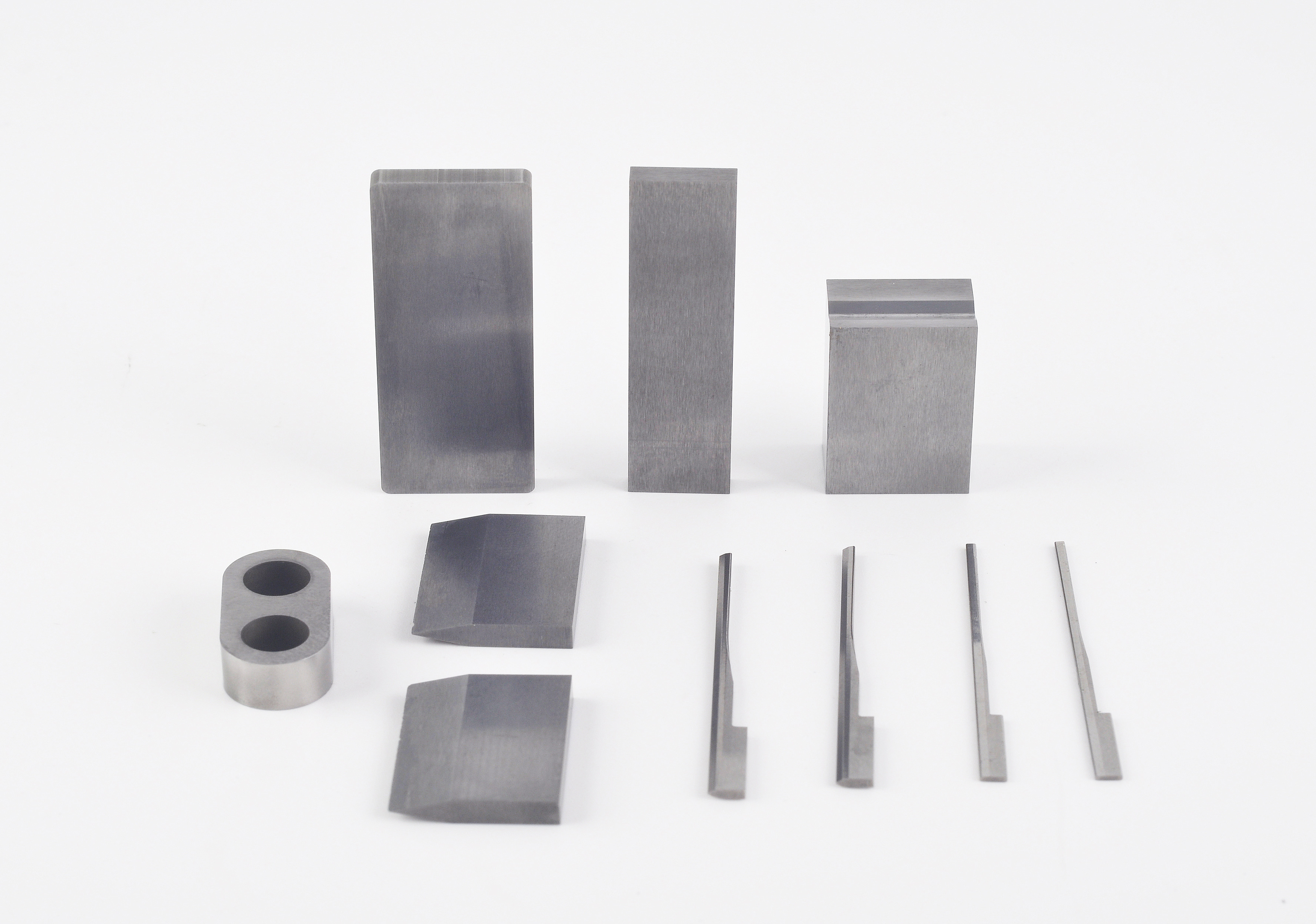

"Penguin" is a registered trademark of Dongguan Penguin Carbide Technology Co., Ltd. The main products of "Penguin" brand are precision tungsten carbide mold, tungsten carbide mold parts, cold heading die punch, tungsten carbide and ceramic precision parts order.

Since its establishment in 2011, “Penguin” has been focusing on the production and development of high-precision tungsten carbide, ceramic and other molds and non-standard parts; adhering to the business philosophy of high performance, excellent quality and delivery on time, it has established a good reputation among a wide range of customers. With comprehensive competitive advantages, it has become one of the top manufacturers of quality manufacturers, and has established long-term strategic partnership with domestic and foreign well-known enterprises including many Fortune 500 companies.

The “Penguin” internal process strictly follows the ISO9001 quality management system, tracking each product's dynamics in real time, realizing the traceability management of each product, and effectively protecting the customer's rights and interests.

“Penguin” adheres to the philosophy of technology, growth and win-win, and creates together with employees, customers, suppliers and shareholders.

Company equipments

CNC Lathe/Turning Wire EDM

Centerless grinding Hole drilling EDM

Round grinding machines

Technical staff

50-person team, technical guarantee

Company development

Penguin, established in 2009 ,

focuses on the Tungsten Carbide Components ,

cutting punches and bushes for matrix manufacturing.

corporate philosophy

Determined, Dedicated and Disciplined

OUR HOT PRODUCTS

WHY CHOOSE US?

Slow wire processing

Slow wire cutting, precision can be directly in place tolerance 0.02

Discharge

The discharge equipment uses Japan's Mitsubishi, Sodick well-known brand machines, the precision can reach 0.002mm

PG optical grinder

PG optical grinding is a precision machining method applied to high-speed mold parts. It can be processed on the screen by 20-50 times magnification according to the size of the workpiece. The tolerance can be guaranteed within 0.002mm.

NEWEST ARTICLE

LINKS

Contact Information

Company Address

东莞海洋之舟

东莞海洋之舟